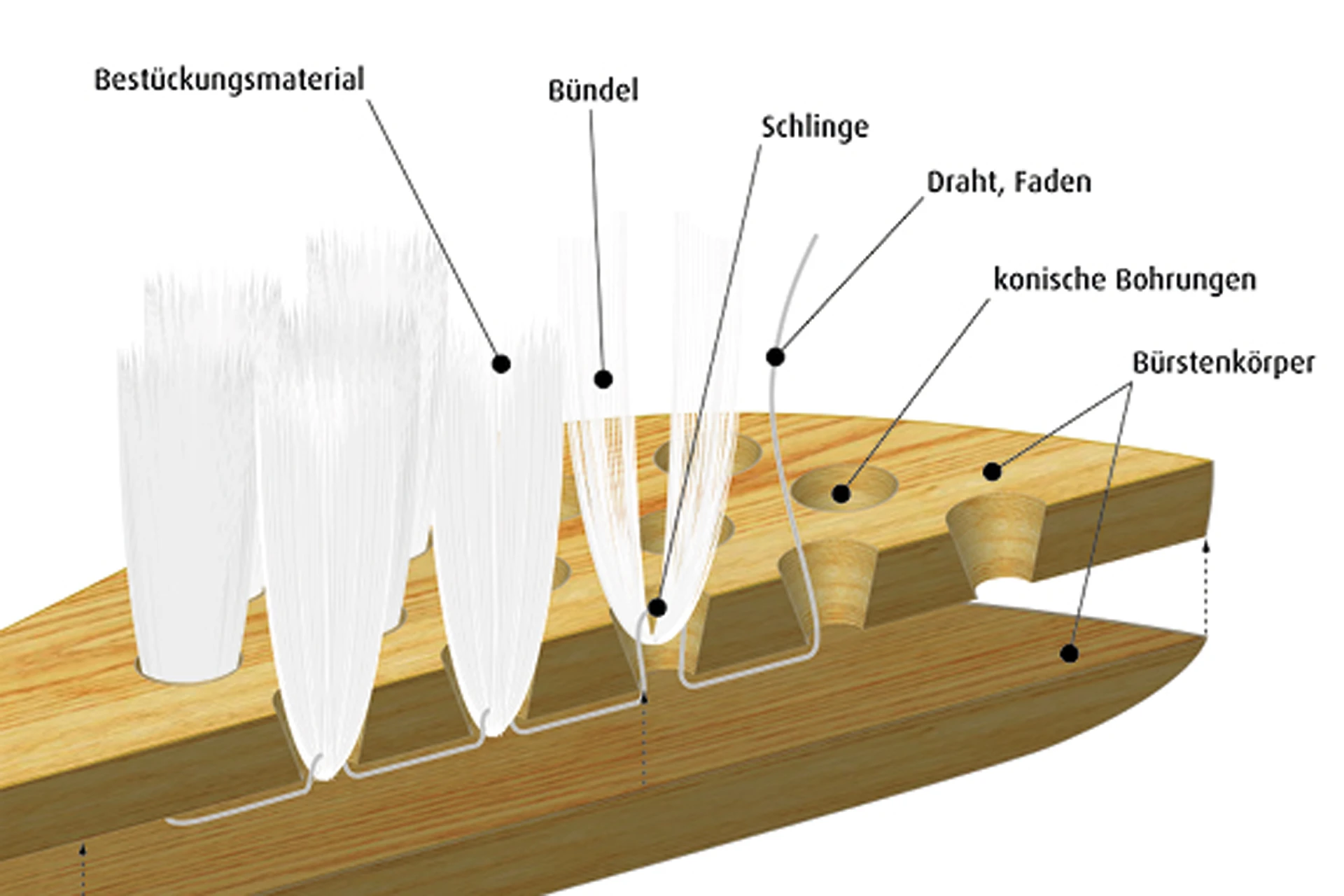

This is how the manual assembly of the inserted hair is done.

The wooden body of the brush is divided into halves: the base, into which the stocking (bristles and related fill material) is pulled, has conical holes. The top has none since it is later put into place to hide the pull-in wire.

First, the wire is passed through the first hole of the brush and a loop is made for the first bundle of stocking. Then, the brushmaker must grasp the correct amount of stocking material in order to be able to fill out the the individual holes in the body of the brush. For this purpose, a brush compartment machine serves to divide the material into uniform bundles.

The material is laid into the wire loop which is then pulled into the body of the brush together with the stocking. In this way, the hole is filled. The wire is inserted into the holes in a certain order and the body of the brush is thus filled with material, loop by loop. After every finished row, the material must be cut to the proper length.So it continues, hole by hole, until the brush body is fully threaded.

At the end, the wire is stitched up so that it cannot come undone. The top is screwed on and the brush is finished!